Emissions Regulations in the Coming Mobility Era

New automotive CO2e emissions regulation in planning around the world provides a unique opportunity to align regulatory practice with the state of the art in environmental product policy, launching a new era of successful environmental legislation free of major unintended consequences.

As with any new technology, there are the complications of making it safe, usable and relevant to the marketplace. And we’re seeing those early growing pains with ride sharing, autonomous and electric vehicles. It’s a difficult process to pioneer technological advancements, especially in the automobile, which has become a personal icon for so many in the world. Not the least of these pains is how to regulate these new mobility technologies, with safety being the foremost driver. With the U.S., Europe and other governments currently involved in researching the best environmental considerations for the impending post-2025 vehicle emissions regulations, the need to future-proof those regulations for a new dynamic in vehicle use and ownership is not only imperative; it’s logical.

As with any new technology, there are the complications of making it safe, usable and relevant to the marketplace. And we’re seeing those early growing pains with ride sharing, autonomous and electric vehicles. It’s a difficult process to pioneer technological advancements, especially in the automobile, which has become a personal icon for so many in the world. Not the least of these pains is how to regulate these new mobility technologies, with safety being the foremost driver. With the U.S., Europe and other governments currently involved in researching the best environmental considerations for the impending post-2025 vehicle emissions regulations, the need to future-proof those regulations for a new dynamic in vehicle use and ownership is not only imperative; it’s logical.

Ride sharing and autonomy are two factors that are both disruptors and solid answers to mega-city transportation and its problems of traffic and pollution. In places like China, where traffic and pollution have both reached threatening levels and car ownership is on a lottery basis, ride-sharing autonomous vehicles are conceptually developing as an affordable service that not only promises to help automate and therefore reduce traffic but provide personal transportation for everyone.

Service is the key word. Mobility company fleet ownership of ride sharing vehicles, think Uber and Didi, will propel the need for differentiation among competitors in order to gain and keep customers and be profitable. That differentiation will come in the form of “pain point” reduction—comfort, safety, reliability, affordability—all of these are not new to automakers. What is new is productivity—the ability for passengers to turn commuting time to productive time, whether that be checking Instagram, making a grocery order or getting a jump on the day’s work.

That will mean more digital content in these vehicles and the need to supply the infrastructure to manage and support that content, within the vehicle as well as in the digital connections. In a report by strategy and investment advisement firm Automobility Limited entitled Competing in the Digital Internet of Mobility, authors Bill Russo, Bevin Jacob and Edward Tse1 note, “Traditional automakers must expand their focus from the product (the “automobile”), to the utility that is derived from the product (“automobility”) and create a business model and digital ecosystem optimized to provide digitally-enabled solutions for both car owners and users.”1

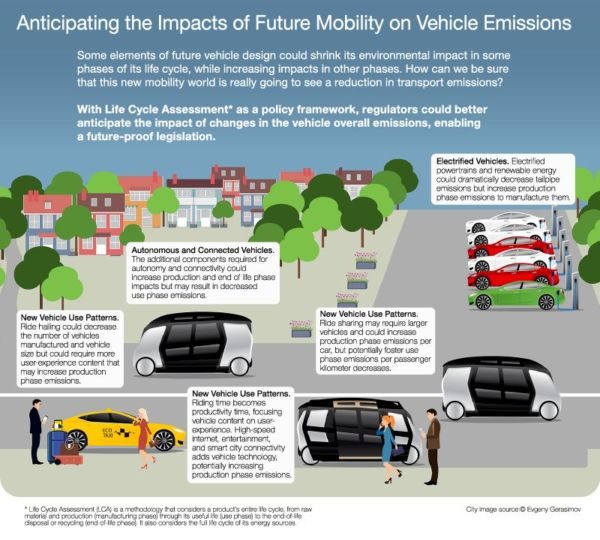

One constant in all this change for the near and distant future is vehicle emissions mitigation, which is also a major impetus towards future mobility. Conditioning people to ride sharing, while creating options for transportation that people will regularly use on a daily basis, will result in reduced tailpipe emissions. But how can we be sure that this new world is really going to see a reduction in transport emissions? With all the added electronics, energy grids that may not be using renewable sources, and vehicle manufacturing complexities driven by autonomous technology hardware and componentry, how will we know that things are getting better?

We believe the answer to those questions is to include Life Cycle Assessment (LCA) as a key element in the next version of vehicle emissions regulation. LCA considers all the emissions created during the life of a product from raw material production to product end-of-life. LCA-based vehicle regulations will foster a holistic view on emissions to make different technologies comparable and enable regulators to better anticipate the consequences of changes in one area, for example a reduction in use phase emissions, on another, such as fuel or vehicle production.

Russ Balzer, WorldAutoSteel LCA Technical Director says, “Only LCA-based regulation is going to provide a way to balance the technical demands and content of these new vehicles with the environmental impacts.”

Says Balzer, “Much of the current regulations around the world began as metrics to achieve reductions in oil consumption. They adopted miles per gallon (kilometers per liter), measured in equivalent tailpipe grams of CO2 per mile (kilometer) as the means to achieve these reductions. It was the right approach to achieve the stated objective. However, extending that same metric toward new objectives for reducing greenhouse gas emissions may result in unintended consequences.”LCA is a well-established, well-supported methodology in the world today, with solid databases already in existence. It is already used by automakers around the world to evaluate their own product development decisions. But it has never been applied in a vehicle regulation.

The European Union may be the first to tackle its inclusion in their next vehicle emission regulation, currently in review. The legislative text recently adopted is, for all intents and purposes, a continuation of the existing CO2 emission legislation with more stringent tailpipe-based targets and verification. Yet it features one notable new element: the idea of reporting on the lifecycle emissions of cars2.

By 2023, the European Commission is tasked with assessing the feasibility of creating an EU methodology for harmonised and consistent reporting of full vehicle lifecycle CO2 emissions.

“With a reporting framework of this kind, regulators could better anticipate the impact of changes in the vehicle fleet on overall emissions and identify the appropriate policy instruments, thereby being able to future-proof the legislation,” Balzer noted.

It will take a while to fully shift vehicle emissions regulations around the world away from tailpipe regulations to a more robust methodology that can help drive the transport emissions reduction we all hope to see, not just today but well into the future in this rapidly changing industry. As LCA is already used by a wide range of stakeholders in the automotive sector, it will also be up to them to contribute to this work and help ensure future debates can draw on their experience on the best way to de-carbonize the road transport sector.

Learn more about Life Cycle Assessment in Vehicle Regulations by browsing our Life Cycle Thinking menu.

1 Competing in the Digital Internet of Mobility, Bill Russo, Bevin Jacob and Edward Tse, LinkedIn Pulse, December 2018

2 REGULATION 2019/631 setting CO2 emission performance standards for new passenger cars and for new light commercial vehicles

Article 7 – Monitoring and reporting of average emissions

10. The Commission shall no later than 2023 evaluate the possibility of developing a common Union methodology for the assessment and the consistent data reporting of the full life-cycle CO2 emissions of passenger cars and light commercial vehicles that are placed on the Union market. The Commission shall transmit to the European Parliament and to the Council that evaluation, including, where appropriate, proposals for follow-up measures, such as legislative proposals.