Steel Strength, the Backbone of the Automotive Industry from worldautosteel on Vimeo.

Watch the SteelYourStrength video to hear automakers, academics and steelmakers talk about AHSS’s role in vehicle design.

Steel Strength, the Backbone of the Automotive Industry

For decades, the steel industry has pioneered a whole new class of materials that are 50% stronger than their predecessors. At the core of this innovation lies the ever-growing Advanced High-Strength Steel (AHSS) family. No other automotive material compares to the variety of steel strength levels today.

This means that the steel can be made thinner, yet retain its strength for vehicle structure performance and safety. Thinner material means less material is used, and therefore components are lighter, contributing to vehicle weight reduction and reduced environmental emissions. Because primary manufacture of steel produces fewer emissions than any other automotive material, it’s a win-win, both in terms of reduced steel manufacturing and vehicle emissions.

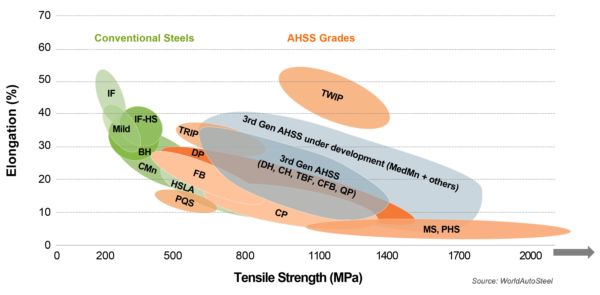

These AHSS capabilities result from their unique combination of strength and ductility. AHSS are complex, sophisticated materials, with carefully selected chemical compositions and multiphase microstructures resulting from precisely controlled heating and cooling processes. Various strengthening mechanisms are employed to achieve a range of strength, ductility, toughness, and fatigue properties.

The AHSS family includes Dual Phase (DP), Complex-Phase (CP), Ferritic-Bainitic (FB), Martensitic (MS), Transformation-Induced Plasticity (TRIP), Hot-Formed (HF), and Twinning-Induced Plasticity (TWIP). These 1st and 2nd Generation AHSS grades are uniquely qualified to meet the functional performance demands of certain parts. For example, DP and TRIP steels are excellent in the crash zones of the car for their high energy absorption. For structural elements of the passenger compartment, extremely high-strength steels, such as Martensitic and boron-based Press Hardened Steels (PHS) result in improved safety performance.

Recently there has been increased funding and research for the development of the “3rd Generation” of AHSS. These are steels with special alloying and thermo-mechanical processing to achieve improved strength-ductility combinations compared to present grades at lower costs. For example, in the U.S., a DOE-sponsored program is enabling the development of 1200 MPa steels with three-fold improvements in ductility. The broad range of properties is best illustrated by the famous Global Formability Diagram, captured in the figure following.

2021 Global Formability Diagram (download the new Diagram here)

The future of steel is expected to deliver even lighter yet stronger designs, thereby further reducing a vehicle’s carbon footprint. The high-strength, recyclability and flexibility of steel make it the appropriate material for the next generation of vehicles: The ability to meet or exceed automotive weight, safety and environmental challenges at little or no significant extra cost.

Automotive body engineers must contend with extreme demands of multiple and complex loading conditions vital to vehicle handling. They also must meet requirements for strength. On our Steel Muscle for New Vehicles page, there are many examples where automakers used AHSS to achieve these goals. The strength of steel is the backbone of the automotive industry. That’s why the steel industry continues to keep pace with its challenges, investing in research and development to tap the amazing power of steel.