The Jeep® Wrangler received a multitude of enhancements versus its predecessor to optimize the ride, handling and sound characteristics while reducing weight and improving fuel economy. Utilizing a body-on-frame design and featuring a five-link suspension system, Wrangler delivers improved on-road driving dynamics, ride comfort and passenger safety.

Proven body-on-frame design is the foundation for legendary Jeep capability

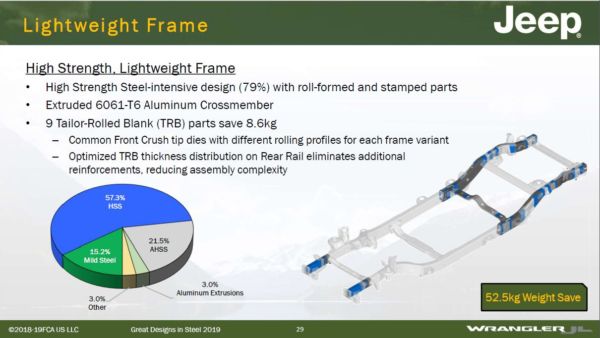

The new Jeep Wrangler’s body-on-frame design is bolstered by eight body mounts on two-door models and 10 on the four-door. A fully boxed frame utilizes High-Strength Steel in all critical areas and hydroformed sections of the front rails set a strong foundation to better handle the front suspension load. Galvanized frame components are utilized for improved corrosion protection.

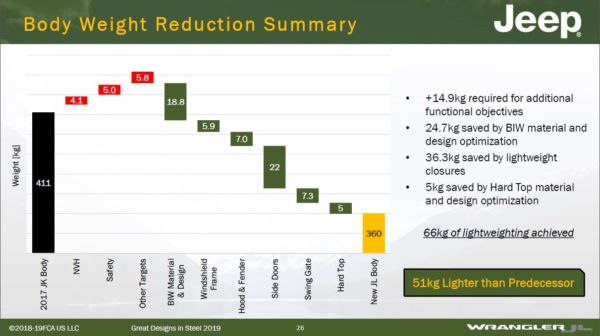

The following chart, taken from a Great Designs in Steel 2019 presentation by April Bagley, Body Systems & Components Engineering at FCA US LLC, clearly illustrates the conflicting challenges that have pressed the automotive industry for the past several decades: Increasing safety with heavier structures and active safety equipment while reducing weight for fuel efficiency and performance. Jeep chose a multi-material strategy, with steel underpinning this historically popular vehicle.

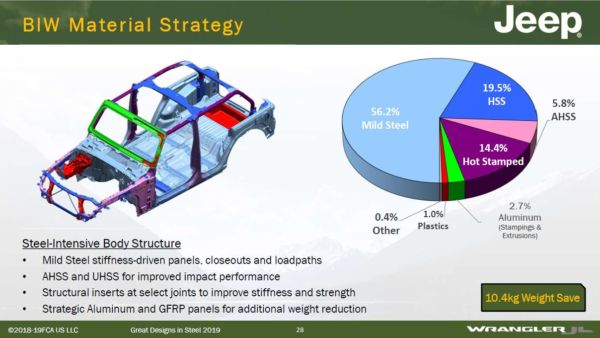

The body structure employees nearly 40% High-Strength and Advanced High-Strength Steels to support lightweighting and performance improvement goals.

The new Jeep Wrangler received an Advanced High-Strength Steel Upperbody Structure, with a Hot Blow-Formed Sport Bars to resist intrusion and distribute loads and High-Strength Steel Front Header/Roof Bows to transfer load cross-car. The Sport Bars are part of the 14.4% of the vehicle made up of Hot Stamped Advanced High-Strength Steels. The tubes were formed by injecting hot air into steel within a die, injecting air to expand the steel to the shape of the die. Water then quenches the part, creating a very lighter weight, significantly stronger structure. The technique also allows for complex sections and dimensions, reducing residual stresses and tighter tolerances, while enabling the elimination of six bolted joints (26 bolts) from the process.

The Sports Bar is also an integral part of the side impact structure along with High-Strength Steel underbody cross-members and Hot Stamped B-Pillar with engineered “soft-zones”. Hot Stamped Reinforcements and High-Strength Steel loadpaths provide a strong safety structure to resist intrusions.

At its foundation is a 79% High-Strength Steel-intensive, lightweight frame, which contributed 52.5 kg of weight savings.

Sources:

FCA Jeep Wrangler Press Kit, 2018

Presentation by April Bagley, Body Systems & Components Engineering, FCA US LLC, “The All-New Jeep Wrangler” presentation, Great Designs in Steel 2019