Liquid Metal Embrittlement (LME) during resistance spot welding (RSW) has long been a concern when working with advanced high-strength steels (AHSS). But the good news? Recent breakthroughs in steel metallurgy, welding practices, and simulation technology are making LME much easier to manage in production environments.

In a new post at AHSS Insights, technical editor Dr. Max Biegler outlines straightforward, practical steps manufacturers can take to identify, prevent, and minimize LME risks during production. From smarter weld process adjustments to in-house testing protocols, this article offers four effective strategies that teams can start using immediately.

Read the full article at AHSS Insights

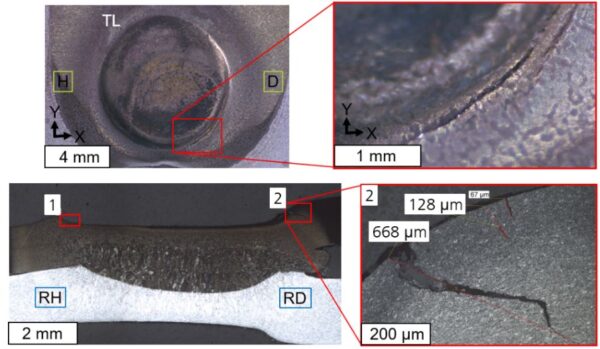

A typical LME crack created under laboratory conditions by deliberately increasing the welding time and introducing 5° electrode tilt