How Digital Twins Are Revolutionizing Welding for Advanced High-Strength Steel

In automotive engineering, welding isn’t just joining metal. it’s where strength, weight savings, and sustainability meet. Today’s challenge? Making tailor-welded blanks (TWBs) from advanced high-strength steels perform perfectly in final components without costly physical testing.

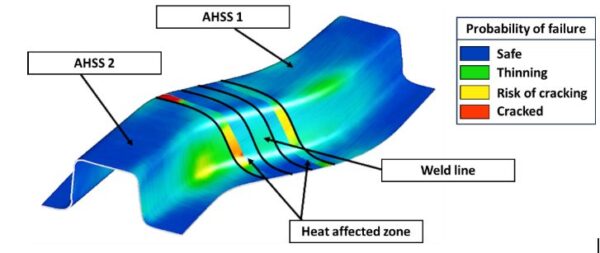

That’s where digitalization steps in. AHSS Insights’ latest piece dives into how digital twins and simulation chains are changing the game for welding and forming processes. Instead of guesswork and iterative tool adjustments, engineers can now virtually test welds, predict heat-affected zones, and fine-tune parameters before a single part hits the line. AHSS Guidelines

This smart approach connects welding and forming simulations in a feedback loop, enabling higher strength, fewer defects, and lighter body-in-white designs — all while saving time, material, and emissions.

Read the full AHSS Insights article to see how digital tools are helping push AHSS to new performance frontiers.